Contact Wheel and Roll Recovery

Your Contact Wheels and Rubber Rolls to Like-New Condition!

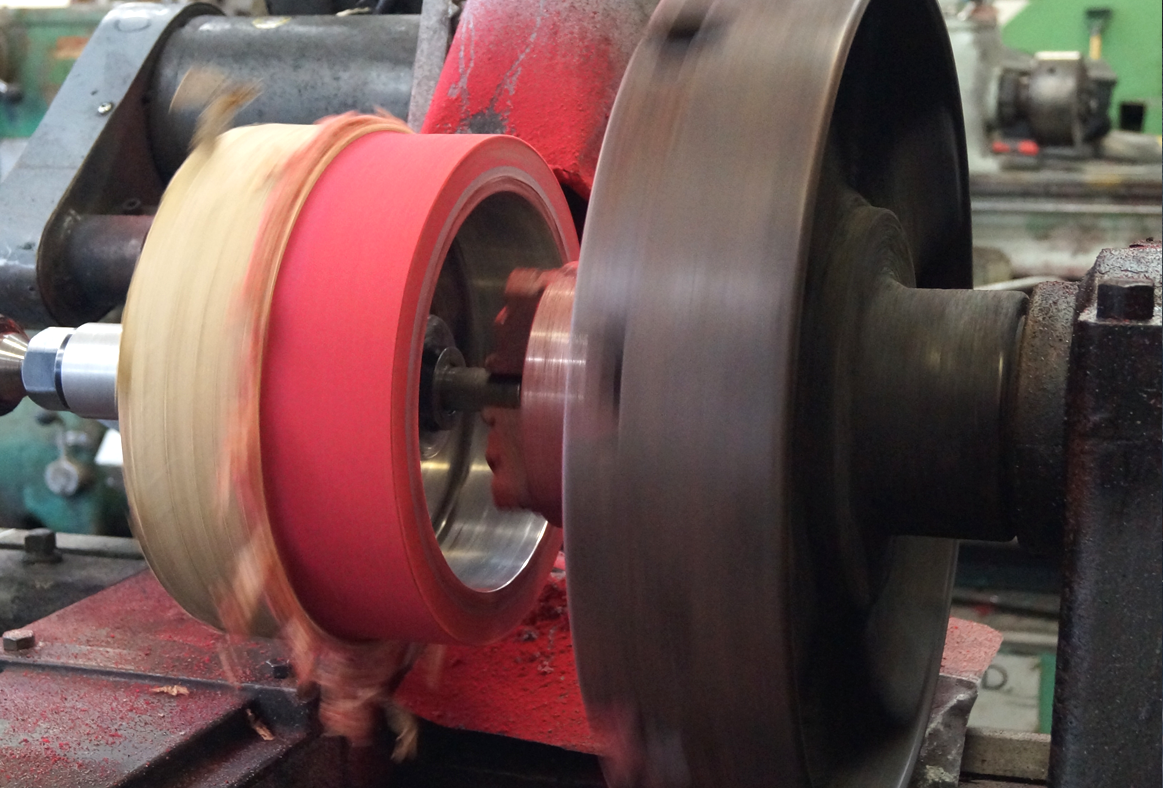

It’s important to maintain your machinery to keep it running at its peak efficiency. Contact Wheel and Rubber Roll Recovery is a great complement to your maintenance programs. You can keep your Contact Wheels, Rubber Rolls, Glue Rolls and large Band Saw Rolls in like-new condition at a fraction of the cost of new ones.

We inspect your wheel cores for bore wear and can repair them, if necessary. All of our recovered Contact Wheels and Rubber Rolls are precision ground and balanced before leaving our factory, to ensure that they will perform as well as a new wheel.

Conestoga Contact Wheel can recoat your Contact Wheels and Rubber Rolls with the material and serration that best fits your needs. Our finishings consist of a wide range of Elastomers, including:

• Natural Rubber

• Neoprene

• Nitriles

• Silicone

• Urethane

• Food Grade Materials … and more

Available in many different durometers, designed for long life and dependable service. Whether smooth, or grooved to the serrated pattern you require, we’ll use the best Elastomer for your application, to ensure the best performance for your usage. Not sure how to choose? See our Contact Wheel Analysis Chart below to compare.

Still not sure? Contact Us to learn more and to discuss Recovery options for your Contact Wheels and Rubber Rolls. We’ll work with you to provide the best recovery for your applications.

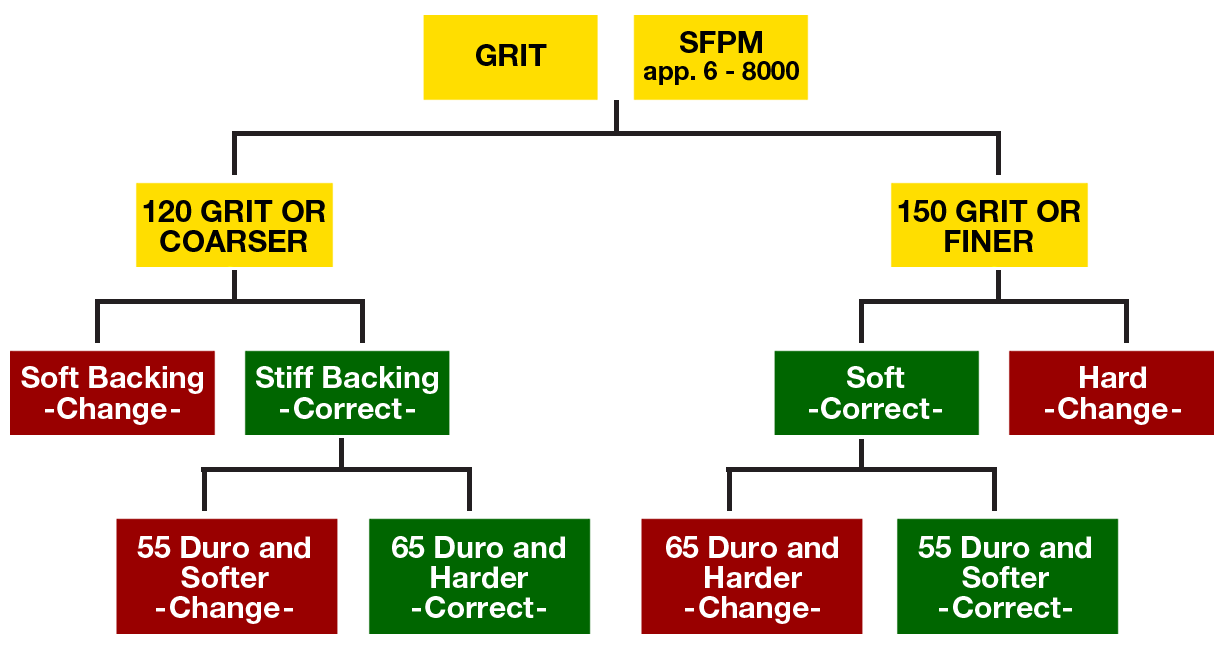

Contact Wheel Analysis

The correct selection of Contact Wheels is as important as your choice of abrasive belt. Not sure what will best suit your needs? Check our Contact Wheel Analysis Chart below to compare.

SERRATED WHEELS: Faster cutting and longer belt life.

HARD WHEELS: Remove more stock than softer wheels, with a coarser finish.

SMALLER WHEEL DIAMETERS: Faster cutting, producing a coarser finish.

Higher speeds will produce a better finish, but caution must be used. Excessive speeds tend to harden a soft wheel. Always use the proper wheel hardness and machine speed.